Liquid Analysis Systems, Inc.

Wastewater Treatment

✔ PH

✔ Turbidity

✔ Trace Analysis

Aerospace

✔ Cleaning

✔ Etching

✔ Anodizing

✔ Plating

Electronics

✔ Plating

✔ Wastewater analysis

Semiconductor

✔ Precision cleaning

✔ Plating

✔ Etching

Automotive

✔ Anodizing

✔ Plating

✔ Wastewater analysis

Liquid Analysis Systems, Inc. has over 30 years of experience in design, manufacture, and servicing of chemical process analysis and control equipment, software, and systems. Our products and services include both standard and custom solutions to chemical process control problems. For the solution to your chemical process control requirements…

Our Online Analyzer Methods

LAS online analyzers are capable of multiple analytical methods and are offered with a full suite of features and options for automatic, unattended operation. Here are our four basic analytical method categories:

Titration

Stable and versatile, carrying out both known and specialty techniques. This well-known method is the most fundamental and established.

PH

Auto-calibrated and temperature-compensated for maximum stability and accuracy. Our at-line approach is also isolated from the process for maximum probe longevity and overall reliability.

Spectroscopy

A rapid, multicomponent analysis method. It is used to distinguish components in mixtures and is often accomplished without reagents or sample loss.

Colorimetry

Utilizing sensitive and proven methods including EPA approved methods for water and wastewater analysis.

Our Analyzer Features and Options

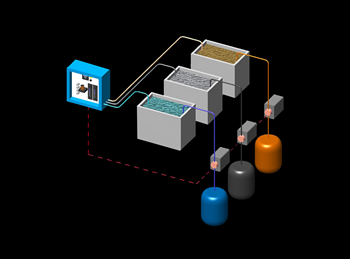

LAS analyzers may be thought of as an atline “laboratory in a box” – complete with sampling, analysis, reporting/alarming, cleanup, and even auto-calibration for continuous, unattended operation. And the LAS design is accomplished with minimum maintenance in view: for example, no peristaltic pumps are used and no pump tubing replacement is required! In most cases, a quarterly PM is all that’s needed.

Auto analysis

configured for your process

Auto sampling

draws and selects from single or multiple streams

Single or multi-parameter analysis

by titration, colorimetry, and spectroscopy

Titration methods

include pH, Redox, color, turbidity

Analysis scheduling

on interval, by event, or at times of day

Result validation

performed by replicate and range checks

Auto calibration

from grab samples or bottled standards

Grab sample port

for bottled samples or standards

Self-test

of all analytical sensors with automatic maintenance alerts

Reagent supply check

with operator alerts

Outputs

for alarming, replenishing, and data transfer

Inputs

for recording process data and synchronizing events